Essential Tools & Materials: Building Your Sublimation Workshop, Craft Room

Setting up your sublimation workspace doesn't have to break the bank, but investing in the right tools from the start will save you time, frustration, and money in the long run. Whether you're converting a spare bedroom or claiming a corner of your kitchen table, having the right equipment and materials makes all the difference between amateur results and professional-quality crafts.

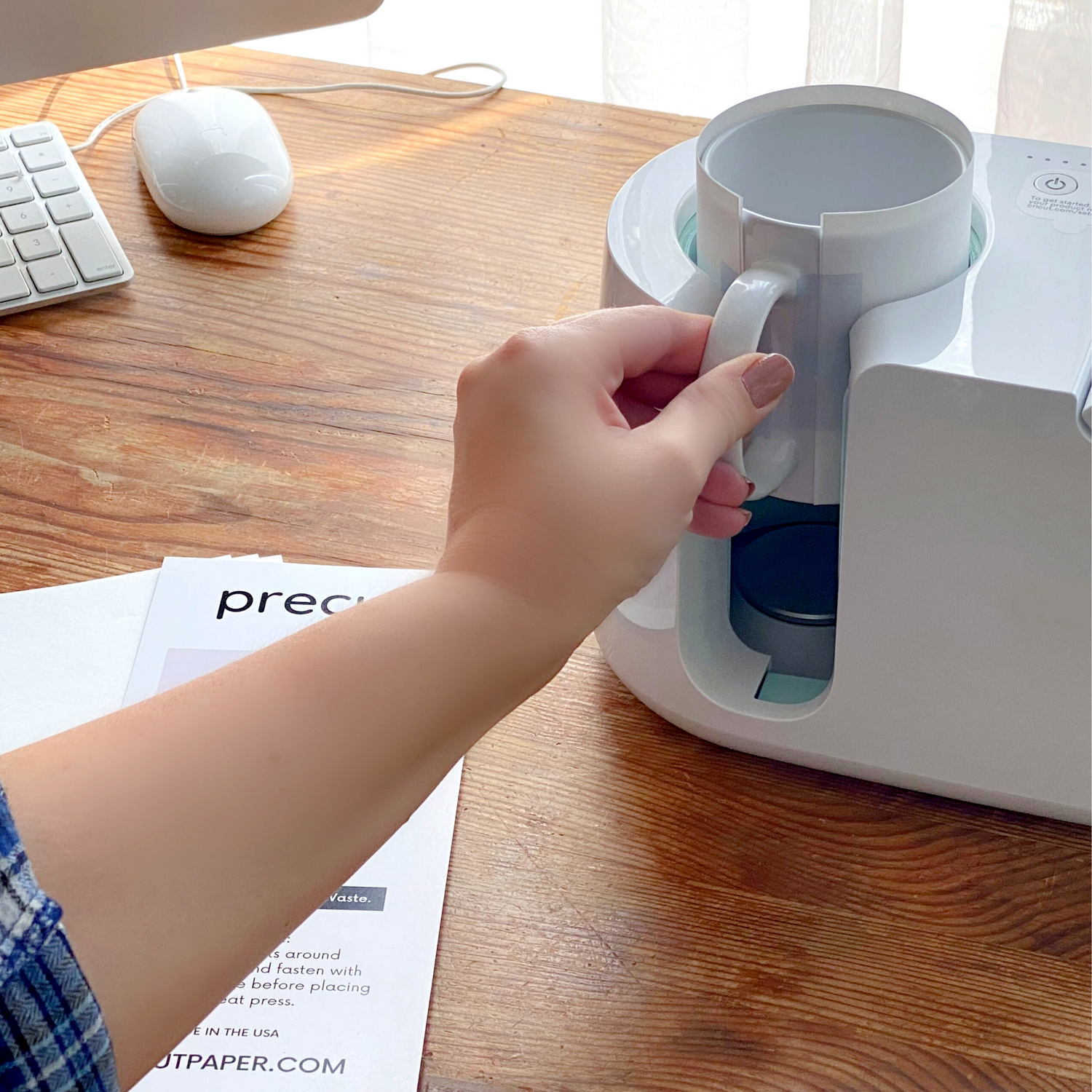

The Foundation: Your Heat Press

Your heat press is the heart of your sublimation operation, so choose wisely. There are several types to consider:

Clamshell Heat Presses

These open like a clamshell, with the heating element on top. They're space-efficient and budget-friendly, making them perfect for beginners or crafters with limited space. Look for models with:

- Digital temperature and time controls

- Even heat distribution across the entire plate

- Adjustable pressure settings

- Safety features like auto-shutoff

Swing-Away Heat Presses

The heating element swings completely away from the base, reducing the risk of burns and making it easier to position your projects. They typically offer more consistent pressure but require more workspace.

3-in-1 or Combo Heat Presses

These include interchangeable platens for different shaped items like mugs, plates, and caps. Great for crafters who want versatility without buying multiple machines.

Pro Tip: Whatever style you choose, invest in a heat press with a warranty and good customer support. A reliable heat press will serve you for years.

Sublimation Printers: Your Creative Engine

Entry-Level Options

The Epson EcoTank ET-2720 or ET-2760 are popular starting points. They're affordable, have refillable ink tanks, and produce good quality prints for most sublimation projects.

Mid-Range Workhorses

The Epson EcoTank ET-4760 offers faster printing, automatic document feeding, and better color accuracy. Perfect for crafters who plan to do higher volumes.

Professional Grade

The Epson SureColor F170 is designed specifically for sublimation, offering superior color management and consistency for serious crafters or small businesses.

Important: Only use sublimation inks in your printer. Regular inkjet inks won't work, and mixing ink types can damage your printer.

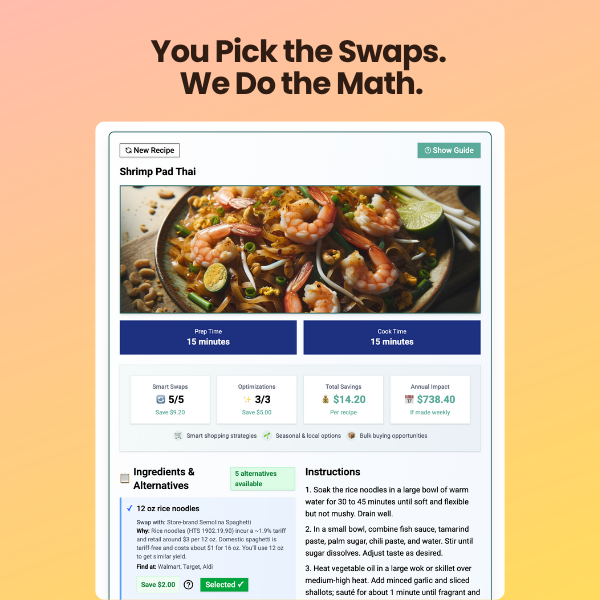

Paper Makes the Difference

Sublimation paper quality directly impacts your final results. Here's what to look for:

Budget Papers

Generic sublimation papers can work for practice projects, but they may have inconsistent coating that leads to blotchy transfers or color bleeding.

Premium Papers

Brands like TexPrint, TruPix, and SubliJet offer consistent coating, better ink absorption, and cleaner releases. Yes, they cost more, but the results justify the investment.

Paper Weight Considerations

- 100gsm: Good for most projects, economical

- 120gsm: Better ink holding capacity, less curling

- 125gsm+: Professional grade, minimal ghosting

Substrates: Where Your Creativity Comes to Life

Apparel

Start with 100% polyester items or poly blends with at least 65% polyester content. Popular choices include:

- Performance t-shirts

- Polyester hoodies

- Athletic wear

- Poly-cotton blends (though colors will be more muted)

Hard Goods

The variety is endless:

- Ceramic mugs with polymer coating

- Aluminum photo panels

- Phone cases

- Keychains

- Coasters

- Puzzles

Quality Check: Always verify that items are specifically labeled as sublimation-ready. Regular ceramics or metals won't work.

The Unsung Hero: Protective Materials

This is where many beginners cut corners, but protective materials are crucial for consistent, professional results.

Butcher Paper

High-quality butcher paper serves multiple purposes:

- Protects your heat press from ink transfer

- Ensures even heat distribution

- Prevents contamination between projects

- Absorbs excess moisture

Why Precut Matters: Cutting your own protective sheets takes time and often results in inconsistent sizes. Precut butcher paper ensures you always have the right dimensions for standard projects, saves prep time, and provides consistent results. When you're in the creative flow, the last thing you want to do is stop to measure and cut protective paper.

Teflon Sheets

Reusable and non-stick, Teflon sheets are perfect for protecting your heat press plates. They're easy to clean and provide excellent heat transfer.

Silicone Mats

Heat-resistant silicone mats protect your work surface and can handle the high temperatures sublimation requires.

Organization and Storage Solutions

Material Storage

- Keep sublimation paper in a cool, dry place

- Store inks away from direct sunlight

- Use clear storage containers for small substrates

- Label everything clearly

Workspace Setup

- Adequate ventilation is essential

- Good lighting for color accuracy

- Easy-to-clean surfaces

- Power strips with surge protection

- Fire extinguisher nearby (safety first!)

Budget-Friendly vs. Professional Setups

Starter Kit ($500-800)

- Basic clamshell heat press

- Entry-level Epson printer

- Starter pack of sublimation inks

- Variety pack of sublimation paper

- Basic protective materials including precut butcher paper

- Sample substrates for practice

Intermediate Setup ($800-1500)

- Mid-range heat press with better controls

- Faster printer with larger ink capacity

- Premium sublimation papers

- Variety of substrates

- Quality protective materials including precut butcher paper

- Better workspace organization

Professional Operation ($1500+)

- Commercial-grade heat press

- Professional sublimation printer

- Bulk materials and supplies

- Quality protective materials including precut butcher paper

- Dedicated workspace

- Business-grade organization systems

- Backup equipment

Money-Saving Tips

- Buy in bulk once you know what works for your projects

- Join craft groups for group buying opportunities

- Compare substrate suppliers – prices vary significantly

- Invest in quality protective materials to extend equipment life

- Keep detailed records of what works to avoid waste

Testing and Quality Control

Before committing to large orders:

- Test each substrate type with your specific setup

- Keep samples of successful settings

- Document temperature, time, and pressure for each material

- Create a reference guide for consistent results

Maintenance Matters

Regular maintenance extends equipment life:

- Clean your heat press plates regularly

- Replace protective materials when they become stained or damaged

- Keep printer heads clean with proper maintenance cycles

- Store inks and papers in optimal conditions

Building for Growth

Start with basics but plan for expansion:

- Choose equipment that can grow with your needs

- Invest in quality items that will last

- Consider your space and how it might evolve

- Think about workflow efficiency from the beginning

Your sublimation workshop is an investment in your creativity and potentially your business. Take time to set it up thoughtfully, invest in quality where it matters most, and don't forget that the small details – like having properly sized protective paper ready to go – can make the difference between a smooth creative session and a frustrating experience.

What's the first piece of equipment you're planning to add to your sublimation setup?