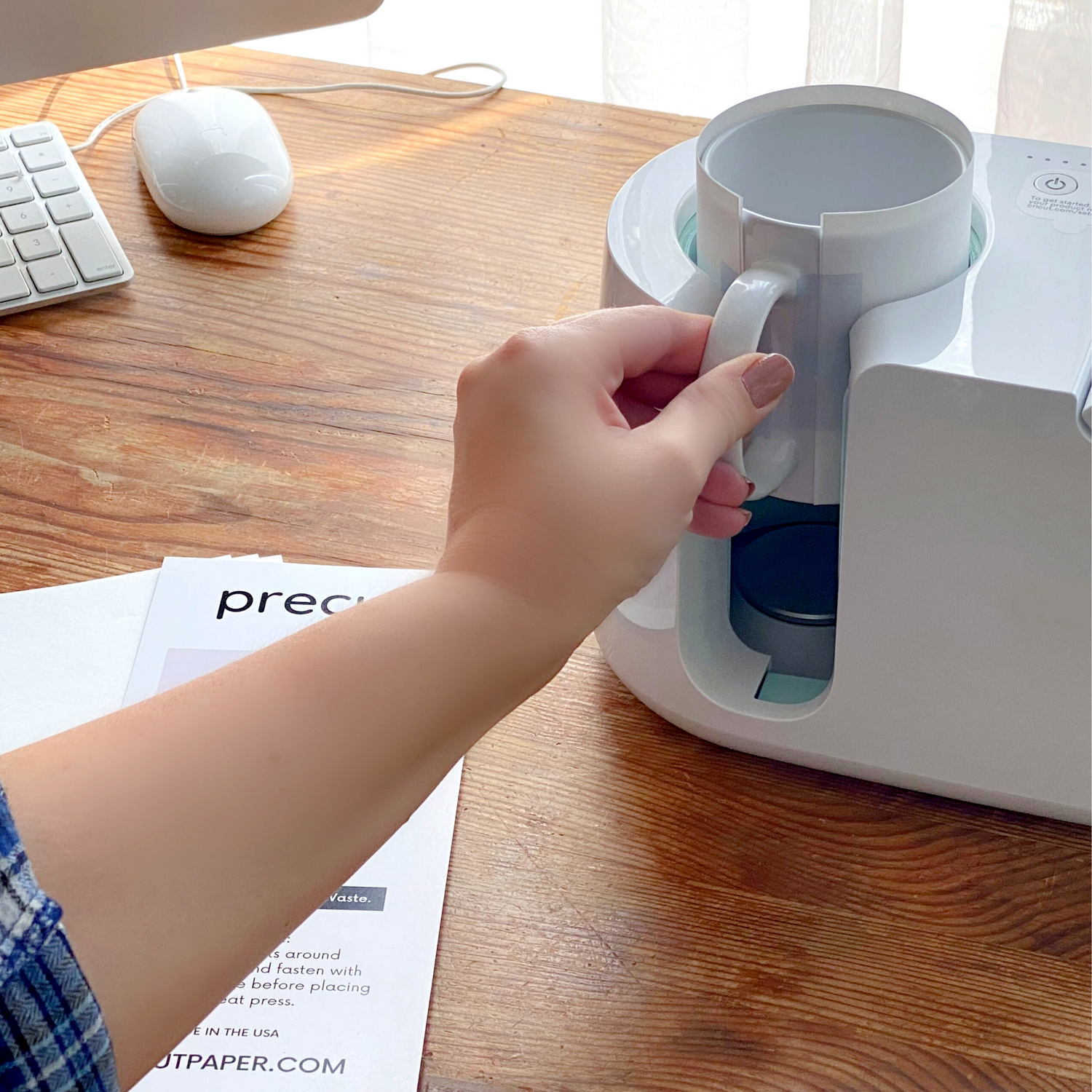

Heat Press Crafts Beyond Sublimation: HTV, Vinyl, and More

Your heat press is capable of so much more than just sublimation! Once you've mastered the art of sublimation printing, you'll discover that your heat press opens up an entire world of crafting possibilities. From heat transfer vinyl to foil applications, rhinestones to patches, your heat press can handle a diverse range of materials and techniques that will expand your creative horizons and business opportunities.

Understanding these different heat press applications not only makes you a more versatile crafter but also allows you to combine techniques for truly unique, professional-looking projects that stand out in the marketplace.

Heat Transfer Vinyl (HTV): The Versatile Favorite

Heat Transfer Vinyl, commonly called HTV, is probably the most popular heat press application after sublimation. Unlike sublimation, which works by infusing ink into polyester substrates, HTV creates designs by cutting vinyl material and heat-pressing it onto fabric surfaces.

Types of HTV

Standard HTV: The most common type, available in dozens of colors and finishes. Perfect for text, simple graphics, and solid color designs.

Glitter HTV: Adds sparkle and texture to designs. Popular for team spirit wear, children's clothing, and decorative projects.

Metallic HTV: Provides a shiny, reflective finish that mimics metallic foil. Great for logos and accent elements.

Patterned HTV: Pre-printed with designs like leopard print, tie-dye, or geometric patterns.

Specialty HTV: Includes glow-in-the-dark, holographic, flocked (fuzzy texture), and other unique finishes.

HTV Application Process

- Design Creation: Create or import your design in cutting software

- Material Preparation: Load HTV onto cutting mat with liner side down

- Cutting: Cut design in reverse (mirror image)

- Weeding: Remove excess vinyl, leaving only your design

- Positioning: Place design on substrate using alignment tools

- Heat Application: Press according to HTV manufacturer specifications

- Finishing: Remove carrier sheet (hot or cold peel depending on HTV type)

HTV vs. Sublimation: When to Choose Which

Choose HTV when:

- Working with cotton or cotton blends

- Creating solid color designs

- Need opaque coverage over dark fabrics

- Want texture or dimensional effects

- Working with small text or intricate cuts

Choose Sublimation when:

- Working with polyester substrates

- Creating photographic or gradient designs

- Want a soft, no-feel finish

- Need vibrant, fade-resistant colors

- Working with hard substrates like mugs or plates

Foil Transfer: Adding Luxury Appeal

Foil transfer creates stunning metallic finishes that add perceived value and luxury to any project. The process uses heat-activated adhesive and metallic foil to create shiny, reflective designs.

Foil Transfer Methods

Foil Transfer Sheets: Pre-cut designs with adhesive backing. Simple to apply but limited to available patterns.

Foil Transfer with Toner: Use a laser printer or photocopier to create toner-based designs, then apply foil over the toner.

Foil Transfer with Adhesive Vinyl: Cut adhesive vinyl designs, apply to substrate, then add foil and heat press.

Application Tips for Foil

- Use medium pressure and relatively low heat (around 280-320°F)

- Apply foil with carrier sheet facing up

- Use protective materials to prevent foil from sticking to press plates

- Work quickly as foil can be temperature-sensitive

Rhinestone and Stud Applications

Adding rhinestones, studs, and other embellishments creates eye-catching designs with dimensional texture. These applications are popular for team wear, fashion items, and special occasion garments.

Rhinestone Application Methods

Individual Placement: Using tweezers or pick-up tools to place each stone individually. Time-consuming but allows for precise placement.

Pre-Made Transfers: Purchase pre-designed rhinestone transfers for quick application.

Template Systems: Use templates to create consistent spacing and alignment for custom designs.

Heat Press Settings for Rhinestones

- Lower temperature than most applications (usually 320-350°F)

- Medium pressure to avoid crushing stones

- Shorter time (15-20 seconds) to prevent overheating

- Use silicone or Teflon pressing sheets for protection

Patch and Appliqué Applications

Patches and appliqués add professional finishing touches to garments and accessories. They can be sewn, heat-pressed, or applied using both methods for maximum security.

Types of Patches

- Embroidered patches: Traditional patches with thread designs

- Printed patches: Sublimated or screen-printed designs on fabric

- Leather patches: For premium, durable applications

- Reflective patches: For safety and visibility applications

Application Considerations

- Pre-heat the garment to remove moisture

- Use appropriate temperature for patch material

- Apply firm, even pressure

- Consider sewing edges for permanent attachment

Combining Techniques for Unique Effects

The real magic happens when you combine different heat press techniques in a single project:

Sublimation + HTV Combinations

- Create full-color sublimated backgrounds with HTV text overlays

- Add HTV borders or accents to sublimated images

- Use HTV to frame sublimated photo transfers

Layering Different Materials

- Apply base sublimation design first

- Add HTV elements after substrate cools

- Finish with foil accents or rhinestone details

- Use different temperatures and times for each layer

Multi-Step Project Planning

When combining techniques, plan your sequence carefully:

- Highest temperature applications first (usually sublimation)

- Allow cooling between steps to prevent damage

- Protect previous layers with appropriate materials

- Document successful combinations for future reference

Protective Materials for Different Applications

Different heat press techniques require specific protective considerations:

For HTV Applications

- Teflon sheets prevent vinyl from sticking to press plates

- Parchment paper can work for light applications

- Avoid wax paper which can melt at high temperatures

For Foil Applications

- Silicone mats prevent foil from adhering to press plates

- Teflon sheets provide release properties

- Proper protective materials prevent waste and mess

For Multi-Layer Projects

- Fresh protective materials between each layer

- Different materials for different techniques

- Properly sized protection prevents edge buildup

Quality protective materials become even more crucial when working with multiple techniques, as contamination from one process can affect subsequent applications.

Business Opportunities with Diverse Techniques

Mastering multiple heat press techniques opens up various business opportunities:

Custom Apparel Services

- Team uniforms with multiple decorating techniques

- Fashion items with mixed media applications

- Special occasion wear with luxury finishes

Promotional Products

- Corporate gifts with professional finishing

- Event merchandise with eye-catching details

- Award items with premium appearance

Repair and Restoration Services

- Fixing damaged sublimation with strategic HTV placement

- Adding new elements to existing garments

- Updating outdated designs with modern techniques

Equipment Considerations for Multiple Techniques

Heat Press Versatility

- Variable temperature control for different materials

- Adjustable pressure for delicate applications

- Interchangeable platens for different substrates

- Timer accuracy for consistent results

Additional Tools

- Cutting machine for HTV preparation

- Weeding tools for vinyl removal

- Alignment tools for precise placement

- Storage solutions for multiple material types

Quality Control Across Techniques

Each technique has specific quality indicators:

HTV Quality Checks

- Complete adhesion without lifting edges

- Smooth application without bubbles

- Proper weeding with no vinyl residue

- Clean, precise cuts

Foil Application Quality

- Complete coverage without gaps

- Good adhesion to base material

- Clean edges without bleeding

- Appropriate shine level

Combined Technique Quality

- Proper layer adhesion

- No interference between techniques

- Consistent appearance across different materials

- Professional overall appearance

Troubleshooting Multi-Technique Projects

Common issues when combining techniques:

Layer Separation: Usually caused by inadequate cooling between applications or incompatible materials.

Uneven Appearance: Often results from inconsistent pressure or temperature across different techniques.

Material Failure: Can occur when protective materials aren't changed between techniques.

Color Interference: May happen when heat from later applications affects earlier layers.

Expanding Your Skill Set

Start Simple: Master one technique before combining multiple methods.

Document Everything: Keep detailed records of successful combinations and settings.

Practice Regularly: Multi-technique projects require muscle memory and timing.

Join Communities: Connect with other crafters who share tips and techniques.

Invest in Quality: Better materials and equipment produce more consistent results across all techniques.

Your heat press is a versatile tool that can handle far more than just sublimation. By mastering multiple techniques and learning to combine them effectively, you'll create unique, professional-quality projects that stand out in any market. The key is understanding each technique's strengths and limitations, then using that knowledge to create something truly special.

Ready to expand your heat press horizons? Download our Multi-Technique Reference Guide with temperature charts, timing guidelines, and step-by-step instructions for combining different heat press applications.

What combination of heat press techniques would you like to try? Share your multi-technique project ideas in the comments – let's inspire each other to push the boundaries of what's possible with our heat presses!